tooj liab ntawv cimuaj qhov tsawg ntawm cov pa oxygen thiab tuaj yeem txuas nrog ntau yam sib txawv substrates, xws li hlau, cov ntaub ntawv insulating.Thiab tooj liab ntawv ci yog siv rau hauv electromagnetic shielding thiab antistatic.Txhawm rau tso cov ntawv ci tooj liab rau ntawm qhov chaw substrate thiab ua ke nrog cov hlau substrate, nws yuav muab kev txuas ntxiv zoo thiab electromagnetic shielding.Nws tuaj yeem muab faib ua: tus kheej-nplaum tooj liab ntawv ci, ib sab tooj liab ntawv ci, ob sab tooj liab ntawv ci thiab lwm yam.

Nyob rau hauv nqe lus no, yog tias koj yuav kawm ntxiv txog cov ntawv ci tooj liab hauv PCB cov txheej txheem tsim khoom, thov xyuas thiab nyeem cov ntsiab lus hauv qab no hauv nqe lus no kom paub ntau ntxiv txog kev tshaj lij.

Dab tsi yog cov yam ntxwv ntawm cov ntawv ci tooj liab hauv PCB kev tsim khoom?

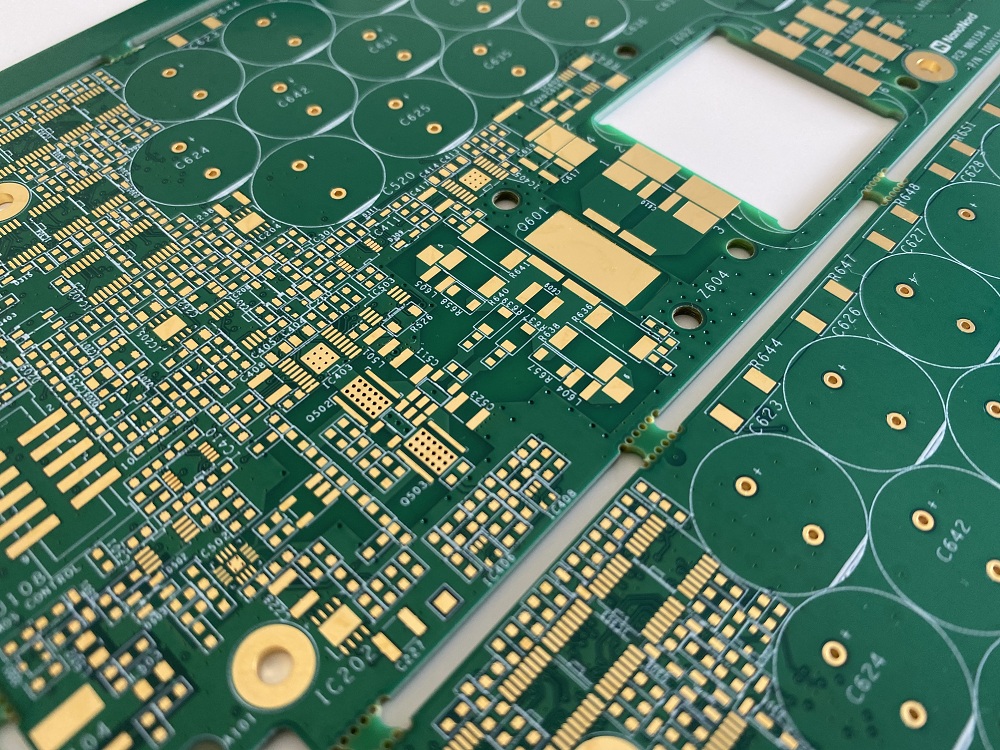

PCB tooj liab ntawv ciyog thawj zaug tooj liab thickness siv rau txheej txheej thiab sab hauv ntawm ib tug multilayer PCB board.Qhov hnyav tooj liab txhais tau tias yog qhov hnyav (hauv ounces) ntawm tooj liab tam sim no hauv ib square feet ntawm cheeb tsam.Qhov no parameter qhia tag nrho cov thickness ntawm tooj liab ntawm txheej.MADPCB siv cov luj tooj liab hauv qab no rau PCB fabrication (pre-phaj).Qhov hnyav ntsuas hauv oz/ft2.Qhov hnyav tooj liab tsim nyog tuaj yeem raug xaiv kom haum raws li qhov tsim nyog.

· Hauv kev tsim PCB, cov ntaub ntawv tooj liab yog nyob rau hauv yob, uas yog qib hluav taws xob nrog purity ntawm 99.7%, thiab thickness ntawm 1/3oz / ft2 (12μm los yog 0.47mil) - 2oz / ft2 (70μm los yog 2.8mil).

· Copper foil muaj qis dua ntawm cov pa oxygen thiab tuaj yeem txuas ua ntej los ntawm cov tuam txhab laminate rau ntau cov ntaub ntawv hauv paus, xws li cov tub ntxhais hlau, polyimide, FR-4, PTFE thiab ceramic, los tsim tooj liab clad laminates.

· Nws kuj tuaj yeem muab tso rau hauv lub rooj tsavxwm multilayer li tooj liab ntawv nws tus kheej ua ntej nias.

· Hauv kev tsim khoom siv PCB, qhov kawg tooj liab tuab ntawm cov khaubncaws sab nraud povtseg tseem tshuav ntawm thawj daim ntawv tooj liab;Nyob rau txheej txheej peb phaj ntxiv 18-30μm tooj liab ntawm cov lem thaum lub sij hawm lub vaj huam sib luag plating txheej txheem.

· Cov tooj liab rau cov txheej txheem txheej txheej ntawm cov boards multilayer yog nyob rau hauv daim ntawv ntawm cov ntawv ci tooj liab thiab nias ua ke nrog cov prepregs lossis cores.Rau siv nrog microvias hauv HDI PCB, cov ntawv ci tooj liab yog ncaj qha rau RCC (resin coated tooj liab).

Vim li cas tooj liab ntawv yuav tsum tau nyob rau hauv PCB manufacturing?

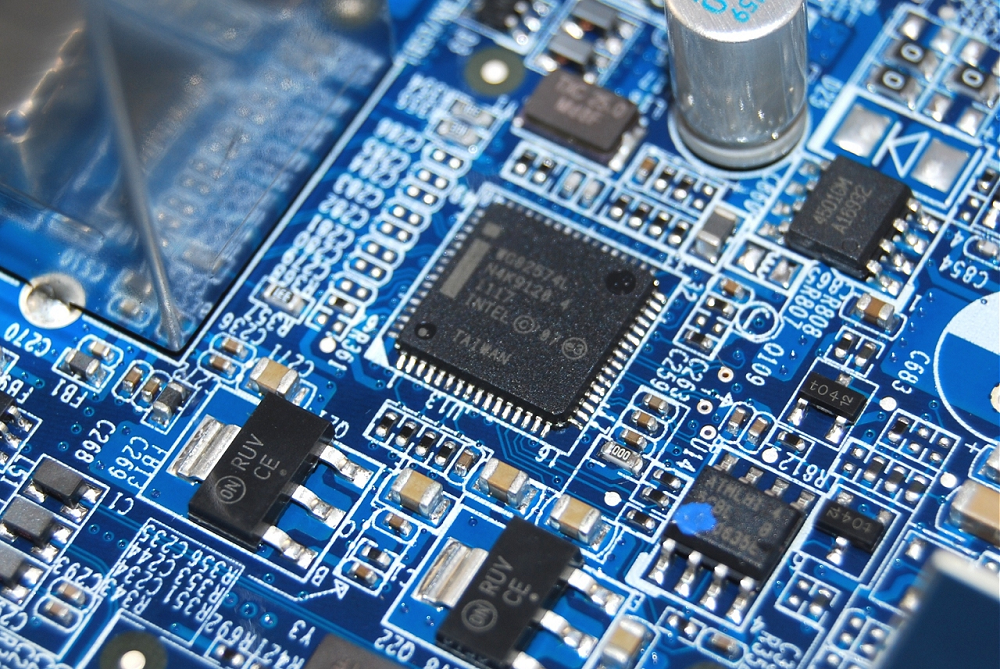

Electronic qib tooj liab ntawv ci (purity ntawm ntau tshaj 99.7%, thickness 5um-105um) yog ib qho ntawm cov ntaub ntawv tseem ceeb ntawm kev lag luam hluav taws xob Kev loj hlob sai ntawm cov ntaub ntawv hluav taws xob kev lag luam, kev siv hluav taws xob qib tooj liab ntawv loj hlob tuaj, cov khoom siv dav siv. hauv kev lag luam tshuab xam zauv, Cov khoom siv sib txuas lus, QA cov cuab yeej, lithium-ion roj teeb, pej xeem TV teeb, video recorders, CD players, copiers, xov tooj, cua txias, automotive electronics, game consoles.

Muaj tooj liab ntawv cituaj yeem muab faib ua ob pawg: dov tooj liab ntawv nyiaj (RA tooj liab ntawv ci) thiab taw tes tooj liab ntawv nyiaj (ED tooj liab ntawv ci), uas daim ntawv teev cov ntawv ci tooj liab muaj qhov zoo ductility thiab lwm yam ntxwv, yog cov txheej txheem muag muag thaum ntxov siv tooj liab ntawv ci, thaum lub electrolytic copper foil yog tus nqi qis ntawm kev tsim cov ntawv ci tooj liab.Raws li dov tooj liab ntawv ci yog ib qho tseem ceeb raw khoom ntawm lub rooj tsavxwm mos, yog li cov yam ntxwv ntawm calendaring tooj liab ntawv nyiaj thiab cov nqi hloov ntawm cov mos board kev lag luam muaj qee yam cuam tshuam.

Dab tsi yog cov txheej txheem tsim qauv ntawm cov ntawv ci tooj liab hauv PCB?

Koj puas paub tias cov ntawv luam tawm Circuit Board muaj ntau heev nyob rau hauv pab pawg ntawm cov khoom siv hluav taws xob?Kuv zoo nkauj npaum li cas ib tug tam sim no nyob rau hauv lub tshuab hluav taws xob koj siv tam sim no.Txawm li cas los xij, siv cov khoom siv hluav taws xob no tsis nkag siab txog lawv cov thev naus laus zis thiab kev tsim qauv kuj yog ib qho kev coj ua.Tib neeg siv cov khoom siv hluav taws xob txhua teev tab sis lawv tsis paub tias lawv ua haujlwm li cas.Yog li ntawm no yog qee qhov tseem ceeb ntawm PCB uas tau hais kom muaj kev nkag siab sai ntawm cov ntawv luam tawm hluav taws xob ua haujlwm li cas.

· Cov ntawv luam tawm Circuit Board yog cov yas yas yooj yim nrog cov iav ntxiv.Cov ntawv ci tooj liab yog siv rau kev taug qab txoj hauv kev thiab nws tso cai rau kev khiav ntawm cov nqi thiab cov teeb liab hauv lub cuab yeej.Cov kab tooj liab yog txoj hauv kev los muab lub zog rau cov khoom sib txawv ntawm cov khoom siv hluav taws xob.Hloov chaw ntawm cov xov hlau, cov kab tooj liab coj tus nqi ntawm cov nqi hauv PCBs.

· PCBs tuaj yeem ua ib txheej thiab ob txheej.Ib txheej PCB yog cov yooj yim.Lawv muaj tooj liab foiling ntawm ib sab thiab sab nraud yog chav rau lwm yam.Thaum nyob rau ntawm ob-txheej PCB, ob sab yog tshwj tseg rau tooj liab foiling.Muab ob npaug rau txheej yog cov PCB nyuaj uas muaj cov kab mob nyuaj rau kev khiav ntawm cov nqi.Tsis muaj tooj liab foils hla ib leeg.Cov PCBs no yuav tsum muaj rau cov khoom siv hluav taws xob hnyav.

· Kuj tseem muaj ob txheej ntawm solders thiab silkscreen ntawm tooj liab PCB.Lub npog ntsej muag yog siv los paub qhov txawv ntawm cov xim ntawm PCB.Muaj ntau cov xim ntawm PCBs muaj xws li ntsuab, ntshav, liab, thiab lwm yam. Solder mask kuj qhia txog tooj liab los ntawm lwm yam hlau kom nkag siab txog kev sib txuas tsis yooj yim.Thaum silkscreen yog cov ntawv nyeem ntawm PCB, cov ntawv sib txawv thiab cov lej tau sau rau ntawm silkscreen rau tus neeg siv thiab tus kws ua haujlwm.

Yuav ua li cas xaiv cov khoom siv rau tooj liab hauv PCB?

Raws li tau hais ua ntej, koj yuav tsum pom cov kauj ruam los ntawm kauj ruam kom nkag siab txog kev tsim qauv ntawm lub rooj tsav xwm luam tawm.Fabrications ntawm cov boards muaj ntau txheej.Cia peb nkag siab qhov no nrog cov kab ke:

Cov khoom siv substrate:

Lub hauv paus hauv paus hla lub rooj tsavxwm yas tswj nrog iav yog lub substrate.Lub substrate yog cov qauv dielectric ntawm ib daim ntawv feem ntau ua los ntawm epoxy resins thiab iav ntawv.Lub substrate yog tsim nyob rau hauv xws li ib txoj kev uas nws muaj peev xwm ua tau raws li qhov yuav tsum tau ua piv txwv hloov kub (TG).

Lamination:

Raws li paub meej los ntawm lub npe, lamination kuj yog ib txoj hauv kev kom tau txais cov khoom xav tau xws li thermal expansion, shear zog, thiab hloov hluav taws xob (TG).Lamination yog ua tiav nyob rau hauv siab.Lamination thiab substrate ua ke ua lub luag haujlwm tseem ceeb hauv kev khiav ntawm cov nqi hluav taws xob hauv PCB.

Post lub sij hawm: Jun-02-2022