Tin Plated Tooj Liab Ntawv Nyiaj

Kev Taw Qhia Txog Khoom

Cov khoom siv tooj liab uas raug tso rau hauv huab cua yuav ua raukev ua kom sovthiab kev tsim cov tooj liab carbonate yooj yim, uas muaj kev tiv taus siab, kev ua hluav taws xob tsis zoo thiab kev poob hluav taws xob siab; tom qab tin plating, cov khoom tooj liab tsim cov yeeb yaj kiab tin dioxide hauv huab cua vim yog cov khoom ntawm tin hlau nws tus kheej kom tiv thaiv kev oxidation ntxiv.

Cov Khoom Siv Tseem Ceeb

●Cov Ntawv Nyiaj Tooj Liab Uas Muaj Kev Ntsuas Siab, Cu (JIS: C1100/ASTM: C11000) cov ntsiab lus ntau dua 99.96%

Cov Khoom Siv Hauv Paus Thickness Ntau Yam

●0.035mm ~ 0.15mm (0.0013 ~ 0.0059 nti)

Qhov Dav Dav ntawm Cov Khoom Siv

●≤300 hli (≤11.8 nti)

Cov Khoom Siv Hauv Paus

●Raws li cov neeg siv khoom xav tau

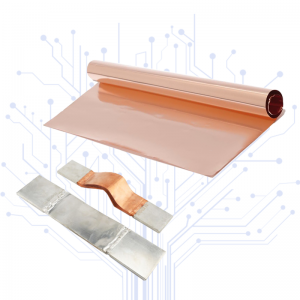

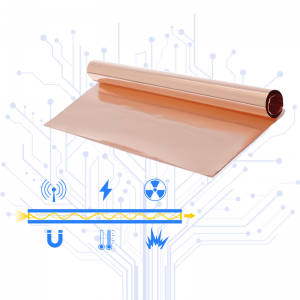

Daim Ntawv Thov

●Cov khoom siv hluav taws xob thiab kev lag luam electronics, pej xeem (xws li: ntim dej haus thiab cov cuab yeej sib cuag zaub mov);

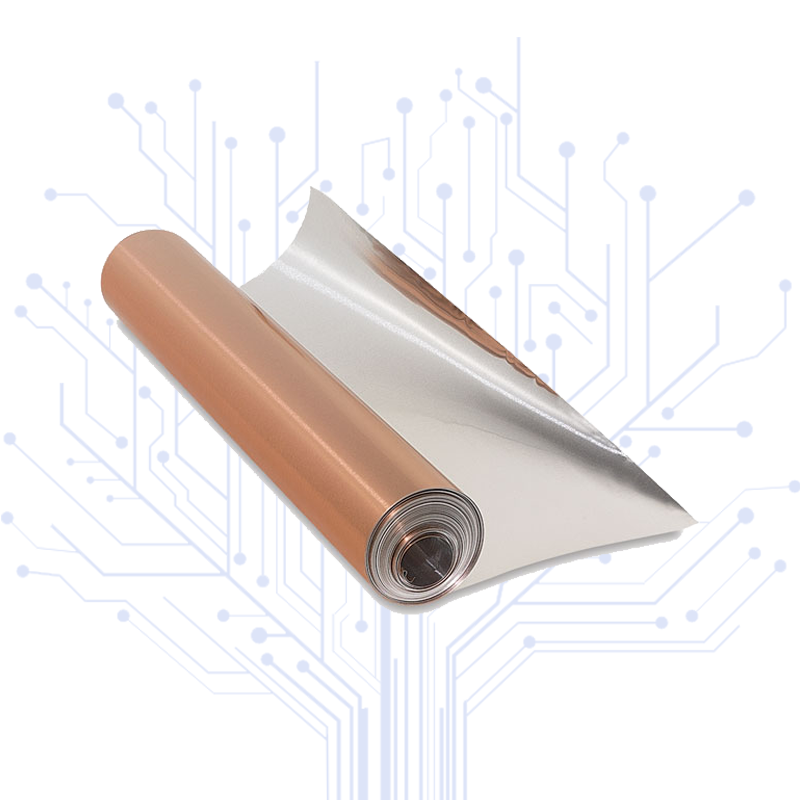

Cov Kev Ntsuas Kev Ua Tau Zoo

| Cov khoom | Cov Tin Plating Uas Siv Tau | Tin Plating uas tsis yog vuam |

| Qhov Dav Dav | ≤600mm (≤23.62inches) | |

| Qhov ntau thiab tsawg | 0.012~0.15 hli (0.00047 nti~0.0059 nti) | |

| Tin txheej Thickness | ≥0.3µm | ≥0.2µm |

| Cov ntsiab lus ntawm Tin Txheej | 65 ~ 92% (Tuaj yeem kho cov ntsiab lus tin raws li cov txheej txheem vuam ntawm cov neeg siv khoom) | 100% Ntshiab Tin |

| Kev Tiv Thaiv Nto Ntawm Tin Txheej(Ω) | 0.3~0.5 | 0.1~0.15 |

| Kev nplaum | 5B | |

| Lub zog tensile | Kev Ua Haujlwm ntawm Cov Khoom Siv Hauv Paus Tom Qab Plating ≤10% | |

| Kev ntev | Kev Ua Haujlwm ntawm Cov Khoom Siv Hauv Paus Tom Qab Plating ≤6% | |

![[VLP] Cov Ntawv Nyiaj Tooj Liab ED Uas Qis Heev](https://cdn.globalso.com/civen-inc/VLP-Very-Low-Profile-ED-Copper-Foil-300x300.png)