Kev lag luam PCB cov ntaub ntawv tau siv sijhawm ntau los tsim cov ntaub ntawv uas muab qhov poob qis tshaj plaws. Rau kev tsim cov qauv ceev thiab zaus siab, qhov poob yuav txwv qhov deb ntawm cov teeb liab thiab ua rau cov teeb liab tsis sib xws, thiab nws yuav tsim qhov sib txawv impedance uas tuaj yeem pom hauv kev ntsuas TDR. Thaum peb tsim cov ntawv luam tawm Circuit Board thiab tsim cov circuits uas ua haujlwm ntawm cov zaus siab dua, nws yuav ntxias kom xaiv cov tooj liab du tshaj plaws hauv txhua qhov qauv koj tsim.

Txawm hais tias nws yog qhov tseeb tias qhov roughness ntawm tooj liab ua rau muaj kev hloov pauv impedance thiab kev poob ntxiv, koj cov ntawv ci tooj liab yuav tsum du npaum li cas? Puas muaj qee txoj hauv kev yooj yim uas koj tuaj yeem siv los kov yeej kev poob yam tsis tau xaiv cov tooj liab du heev rau txhua tus qauv tsim? Peb yuav saib cov ntsiab lus no hauv tsab xov xwm no, nrog rau yam koj tuaj yeem nrhiav yog tias koj pib yuav cov ntaub ntawv PCB stackup.

Hom ntawmPCB Tooj Liab Ntawv Nyiaj

Feem ntau thaum peb tham txog tooj liab ntawm cov ntaub ntawv PCB, peb tsis tham txog hom tooj liab tshwj xeeb, peb tsuas yog tham txog nws qhov roughness. Cov txheej txheem sib txawv ntawm kev tso tooj liab tsim cov yeeb yaj kiab nrog cov nqi roughness sib txawv, uas tuaj yeem pom tseeb hauv daim duab scanning electron microscope (SEM). Yog tias koj yuav ua haujlwm ntawm qhov zaus siab (feem ntau 5 GHz WiFi lossis siab dua) lossis ntawm qhov ceev siab, ces xyuam xim rau hom tooj liab teev tseg hauv koj daim ntawv qhia khoom siv.

Tsis tas li ntawd, nco ntsoov nkag siab lub ntsiab lus ntawm Dk tus nqi hauv daim ntawv teev cov ntaub ntawv. Saib qhov kev sib tham podcast no nrog John Coonrod los ntawm Rogers kom paub ntau ntxiv txog Dk cov lus qhia. Nrog rau qhov ntawd hauv siab, cia peb saib qee hom PCB tooj liab sib txawv.

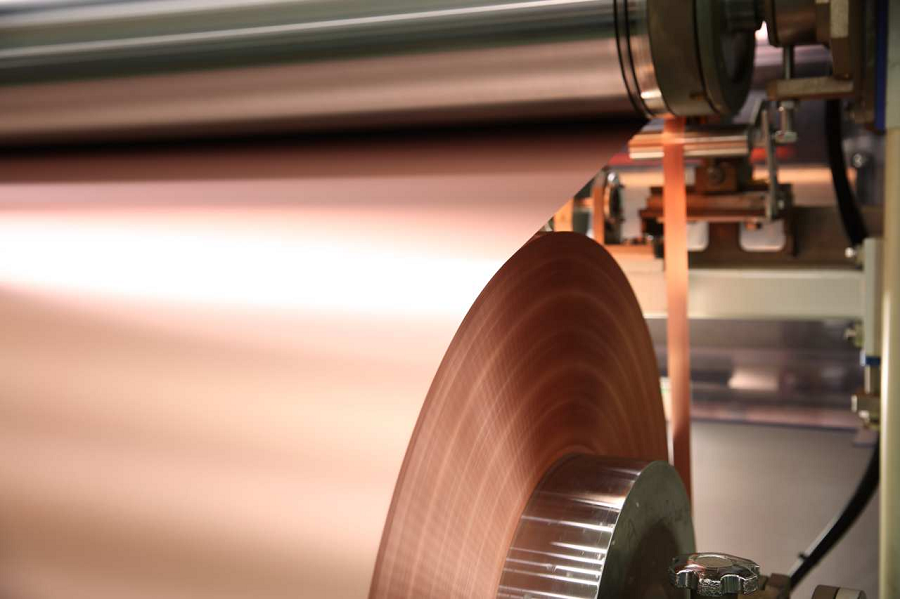

Electrodeposited

Hauv cov txheej txheem no, lub nruas raug tig los ntawm cov kua electrolytic, thiab cov tshuaj electrodeposition siv los "loj hlob" cov ntawv ci tooj liab rau ntawm lub nruas. Thaum lub nruas tig, cov zaj duab xis tooj liab uas tshwm sim maj mam qhwv rau ntawm lub roller, muab ib daim ntawv tooj liab txuas ntxiv uas tom qab ntawd tuaj yeem dov rau ntawm lub laminate. Sab nruas ntawm cov tooj liab yuav zoo ib yam li qhov roughness ntawm lub nruas, thaum sab uas raug nthuav tawm yuav rougher dua.

Cov ntawv ci tooj liab electrodeposited PCB

Kev tsim cov tooj liab electrodeposited.

Yuav kom siv tau rau hauv cov txheej txheem tsim PCB tus qauv, sab ntxhib ntawm cov tooj liab yuav tsum tau sib txuas nrog cov iav-resin dielectric ua ntej. Cov tooj liab uas tseem tshuav (sab nruas) yuav tsum tau ua kom ntxhib los ntawm kev siv tshuaj lom neeg (piv txwv li, nrog plasma etching) ua ntej nws tuaj yeem siv rau hauv cov txheej txheem lamination tooj liab. Qhov no yuav ua kom ntseeg tau tias nws tuaj yeem sib txuas rau txheej tom ntej hauv PCB stackup.

Tooj Liab Electrodeposited Kho Qhov Chaw

Kuv tsis paub lo lus zoo tshaj plaws uas suav nrog txhua hom kev kho saum npoo sib txawvcov ntawv ci tooj liab, yog li ntawd lub npe saum toj no. Cov ntaub ntawv tooj liab no paub zoo tshaj plaws li cov ntawv ci kho rov qab, txawm hais tias muaj ob qho kev hloov pauv ntxiv (saib hauv qab no).

Cov ntawv ci uas kho rov qab siv cov kev kho saum npoo uas siv rau sab du (sab nruas) ntawm daim ntawv tooj liab electrodeposited. Ib txheej kho tsuas yog ib txheej nyias uas txhob txwm ua rau tooj liab ntxhib, yog li nws yuav muaj kev sib txuas ntau dua rau cov khoom siv dielectric. Cov kev kho no kuj ua haujlwm ua ib qho kev thaiv oxidation uas tiv thaiv kev xeb. Thaum cov tooj liab no siv los tsim cov vaj huam sib luag laminate, sab kho tau sib txuas rau dielectric, thiab sab ntxhib seem tseem raug nthuav tawm. Sab raug nthuav tawm yuav tsis xav tau kev ntxhib ntxiv ua ntej etching; nws yuav twb muaj zog txaus los txuas rau txheej tom ntej hauv PCB stackup.

Peb qhov kev hloov pauv ntawm cov ntawv ci tooj liab rov qab kho suav nrog:

Cov ntawv ci tooj liab uas kub thiab ntev (HTE): Qhov no yog cov ntawv ci tooj liab electrodeposited uas ua raws li IPC-4562 Qib 3 cov lus qhia. Lub ntsej muag uas raug nthuav tawm kuj tseem kho nrog cov khoom thaiv oxidation kom tiv thaiv kev xeb thaum lub sijhawm khaws cia.

Cov ntawv ci kho ob zaug: Hauv cov ntawv ci tooj liab no, kev kho mob raug siv rau ob sab ntawm zaj duab xis. Cov khoom siv no qee zaum hu ua ntawv ci kho sab nruas.

Tooj liab tiv taus: Qhov no feem ntau tsis raug cais ua tooj liab uas tau kho saum npoo. Cov ntawv ci tooj liab no siv cov xim hlau txheej rau sab matte ntawm tooj liab, uas tom qab ntawd raug ua kom ntxhib mus rau qib xav tau.

Kev siv tshuaj kho qhov chaw ntawm cov khoom siv tooj liab no yooj yim heev: cov ntawv ci raug dov los ntawm cov dej electrolyte ntxiv uas siv cov plating tooj liab thib ob, ua raws li txheej noob thaiv, thiab thaum kawg txheej zaj duab xis tiv thaiv kev puas tsuaj.

PCB tooj liab ntawv ci

Cov txheej txheem kho qhov chaw rau cov ntawv ci tooj liab. [Tau los ntawm: Pytel, Steven G., et al. "Kev tshuaj xyuas kev kho tooj liab thiab cov teebmeem ntawm kev nthuav dav ntawm lub teeb liab." Xyoo 2008 58th Electronic Components and Technology Conference, pp. 1144-1149. IEEE, 2008.]

Nrog cov txheej txheem no, koj muaj cov khoom siv uas tuaj yeem siv tau yooj yim hauv cov txheej txheem tsim cov laug cam nrog kev ua tiav tsawg kawg nkaus.

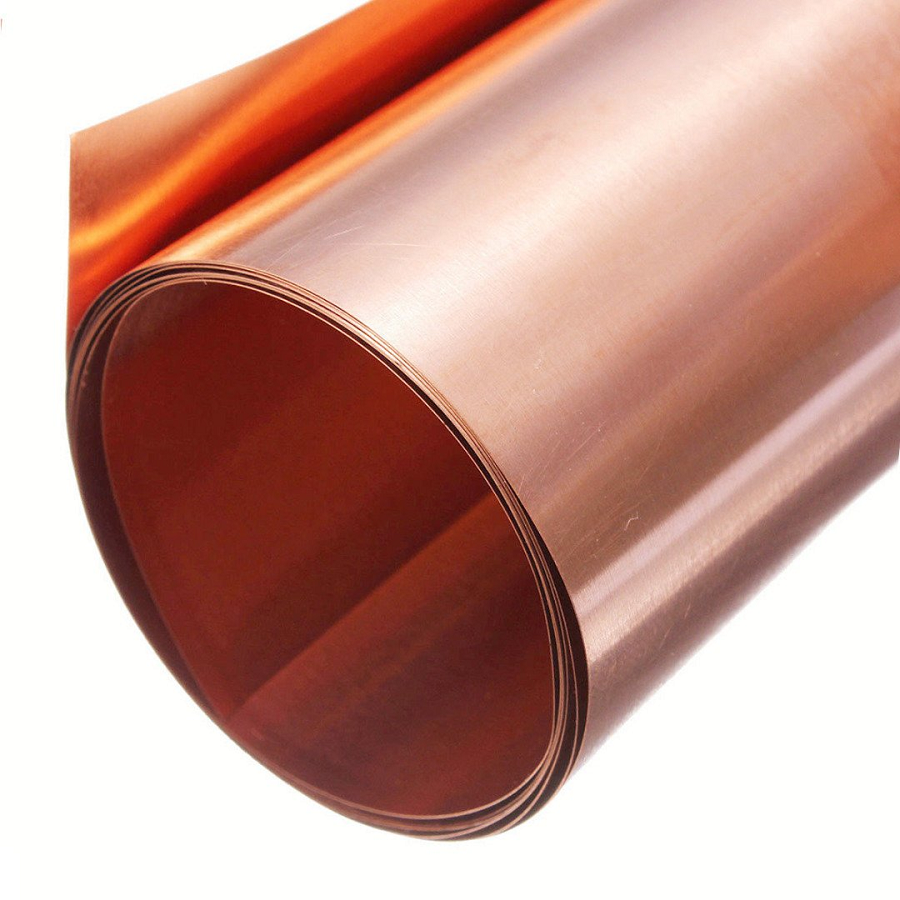

Tooj Liab Uas Tau Muab Kauv Los Ntawm Cov Hlau

Cov ntawv ci tooj liab uas tau dov thiab annealed yuav hla ib lub yob ntawm cov ntawv ci tooj liab los ntawm ob lub rollers, uas yuav txias-dov lub ntawv tooj liab mus rau qhov tuab xav tau. Qhov roughness ntawm cov ntawv ci uas tau txais yuav txawv nyob ntawm cov kev ntsuas dov (kev ceev, siab, thiab lwm yam).

Daim ntawv uas tau los ntawm qhov no yuav du heev, thiab pom tau cov kab txaij ntawm qhov saum npoo ntawm daim ntawv tooj liab uas tau dov thiab kub hnyiab. Cov duab hauv qab no qhia txog kev sib piv ntawm cov ntawv ci tooj liab electrodeposited thiab cov ntawv ci uas tau dov thiab kub hnyiab.

Kev sib piv ntawm PCB tooj liab ntawv ci

Kev sib piv ntawm cov ntawv ci electrodeposited vs. dov-annealed.

Tooj Liab Qis Profile

Qhov no tsis tas yuav yog hom ntawv ci tooj liab uas koj yuav tsim nrog lwm txoj hauv kev. Tooj liab qis-profile yog tooj liab electrodeposited uas tau kho thiab hloov kho nrog cov txheej txheem micro-roughening kom muab qhov nruab nrab qis heev nrog qhov roughening txaus rau kev lo rau lub substrate. Cov txheej txheem rau kev tsim cov ntawv ci tooj liab no feem ntau yog proprietary. Cov ntawv ci no feem ntau yog categorized li ultra-low profile (ULP), very low profile (VLP), thiab tsuas yog qis-profile (LP, kwv yees li 1 micron nruab nrab roughness).

Cov ntawv sib xws:

Vim li cas cov ntawv ci tooj liab siv rau hauv PCB Manufacturing?

Cov Ntawv Nyiaj Tooj Liab Siv Hauv Cov Rooj Sib Tham Luam Tawm

Lub sijhawm tshaj tawm: Lub Rau Hli-16-2022