Feem ntau peb raug nug txog kev yooj ywm. Tau kawg, vim li cas koj thiaj xav tau lub rooj tsavxwm "flex"?

"Puas yog lub rooj tsavxwm flex yuav tawg yog tias siv ED tooj liab rau nws?"

Hauv tsab xov xwm no peb xav tshawb nrhiav ob yam khoom sib txawv (ED-Electrodeposited thiab RA-rolled-annealed) thiab saib lawv qhov cuam tshuam rau lub neej ntev ntawm lub voj voog. Txawm hais tias kev lag luam flex nkag siab zoo, peb tsis tau txais cov lus tseem ceeb ntawd rau tus tsim lub rooj tsavxwm.

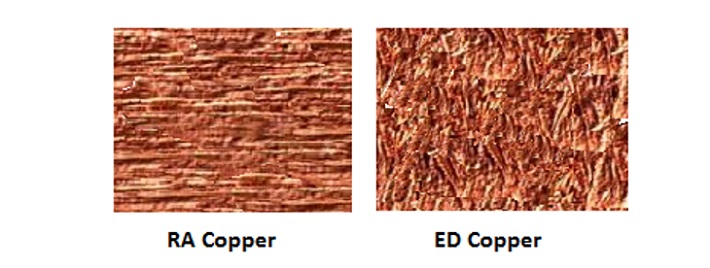

Cia peb siv sijhawm los tshuaj xyuas ob hom ntawv ci no. Nov yog qhov kev soj ntsuam ntawm RA Copper thiab ED Copper:

Kev yooj ywm ntawm cov tooj liab los ntawm ntau yam. Tau kawg, cov tooj liab nyias dua, cov laug cam yooj ywm dua. Ntxiv rau qhov tuab (lossis nyias), cov noob tooj liab kuj cuam tshuam rau kev yooj ywm. Muaj ob hom tooj liab uas siv rau hauv PCB thiab flex circuit kev lag luam: ED thiab RA raws li tau hais los saum toj no.

Dov Anneal Tooj Liab Ntawv Nyiaj (RA tooj liab)

Cov Tooj Liab Dov Annealed (RA) tau siv dav hauv kev tsim cov voj voog flex thiab kev lag luam PCB rigid-flex rau ntau xyoo lawm.

Cov qauv ntawm cov noob thiab qhov chaw du yog qhov zoo tagnrho rau cov kev siv hluav taws xob uas hloov pauv tau yooj yim. Lwm qhov chaw txaus siab nrog cov hom tooj liab dov muaj nyob rau hauv cov teeb liab thiab cov ntawv thov uas muaj zaus siab.

Nws tau raug pov thawj tias qhov roughness ntawm tooj liab tuaj yeem cuam tshuam rau qhov poob ntawm qhov ntxig zaus siab thiab qhov saum npoo tooj liab du dua yog qhov zoo.

Cov Ntawv Nyiaj Tooj Liab Electrolysis Deposition (ED tooj liab)

Nrog ED tooj liab, muaj ntau yam sib txawv ntawm cov ntawv ci txog qhov roughness ntawm qhov chaw, kev kho mob, cov qauv noob, thiab lwm yam. Raws li cov lus dav dav, ED tooj liab muaj cov qauv noob ntsug. Tus qauv ED tooj liab feem ntau muaj qhov profile siab lossis qhov chaw ntxhib piv rau Rolled Annealed (RA) Tooj Liab. ED tooj liab feem ntau tsis muaj kev ywj pheej thiab tsis txhawb nqa kev ncaj ncees ntawm lub teeb liab.

Tooj liab EA tsis haum rau cov kab me me thiab tsis kam khoov zoo yog li tooj liab RA siv rau PCB yooj ywm.

Txawm li cas los xij, tsis muaj laj thawj yuav ntshai ED tooj liab hauv cov ntawv thov dynamic.

Txawm li cas los xij, tsis muaj laj thawj ntshai ED tooj liab hauv cov ntawv thov dynamic. Ntawm qhov tsis sib xws, nws yog qhov kev xaiv de facto hauv cov ntawv thov nyias, sib dua uas xav tau cov nqi siab. Qhov kev txhawj xeeb tsuas yog kev tswj hwm ceev faj ntawm qhov twg peb siv "additive" plating rau PTH txheej txheem. RA ntawv ci yog tib qho kev xaiv muaj rau cov tooj liab hnyav dua (saum toj no 1 oz.) qhov twg cov ntawv thov hnyav dua thiab dynamic flexing yog qhov yuav tsum tau ua.

Yuav kom nkag siab txog qhov zoo thiab qhov tsis zoo ntawm ob hom ntaub ntawv no, nws yog ib qho tseem ceeb kom nkag siab txog cov txiaj ntsig ntawm tus nqi thiab kev ua tau zoo ntawm ob hom ntawv ci tooj liab no thiab, qhov tseem ceeb ib yam, dab tsi muaj muag hauv khw. Tus tsim qauv yuav tsum xav txog tsis yog tsuas yog dab tsi yuav ua haujlwm xwb, tab sis seb nws puas tuaj yeem yuav tau ntawm tus nqi uas yuav tsis thawb cov khoom kawg tawm ntawm kev ua lag luam raws li tus nqi.

Lub sijhawm tshaj tawm: Tsib Hlis-22-2022