Kev faib tawm ntawm ED tooj liab ntawv ci:

1. Raws li kev ua tau zoo, ED tooj liab ntawv ci tuaj yeem faib ua plaub hom: STD, HD, HTE thiab ANN

2. Raws li cov ntsiab lus ntawm qhov chaw,ED tooj liab ntawv ciMuaj peev xwm muab faib ua plaub hom: tsis muaj kev kho saum npoo thiab tsis tiv thaiv xeb, kev kho saum npoo ntawm kev tiv thaiv xeb, ib sab ua haujlwm tiv thaiv xeb thiab ob chav ua haujlwm nrog kev tiv thaiv xeb.

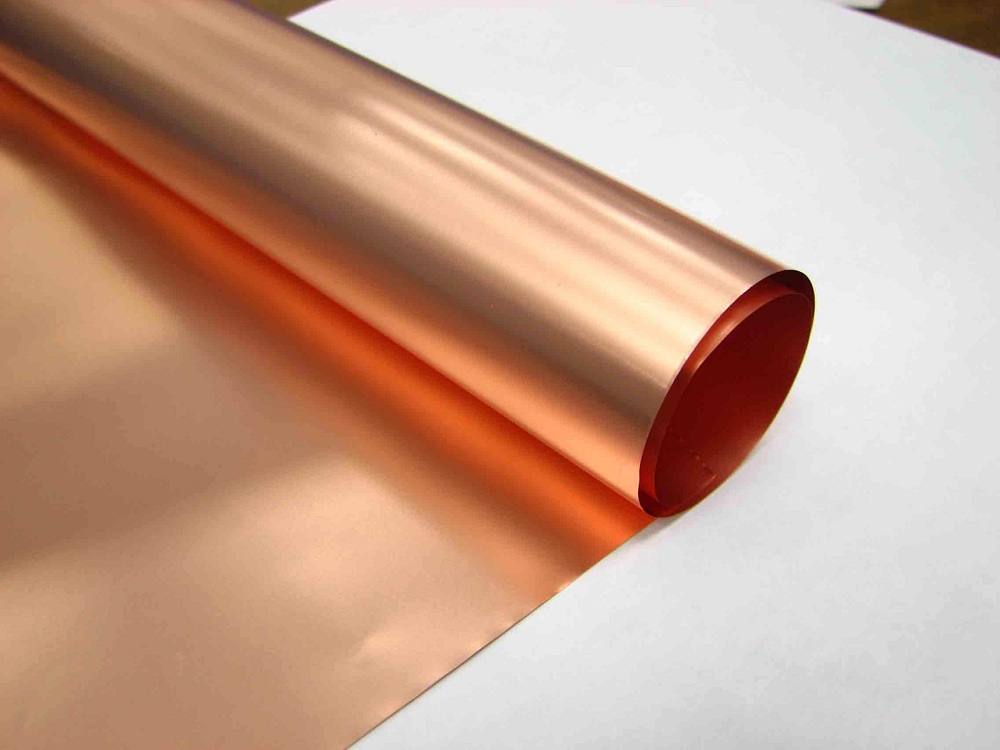

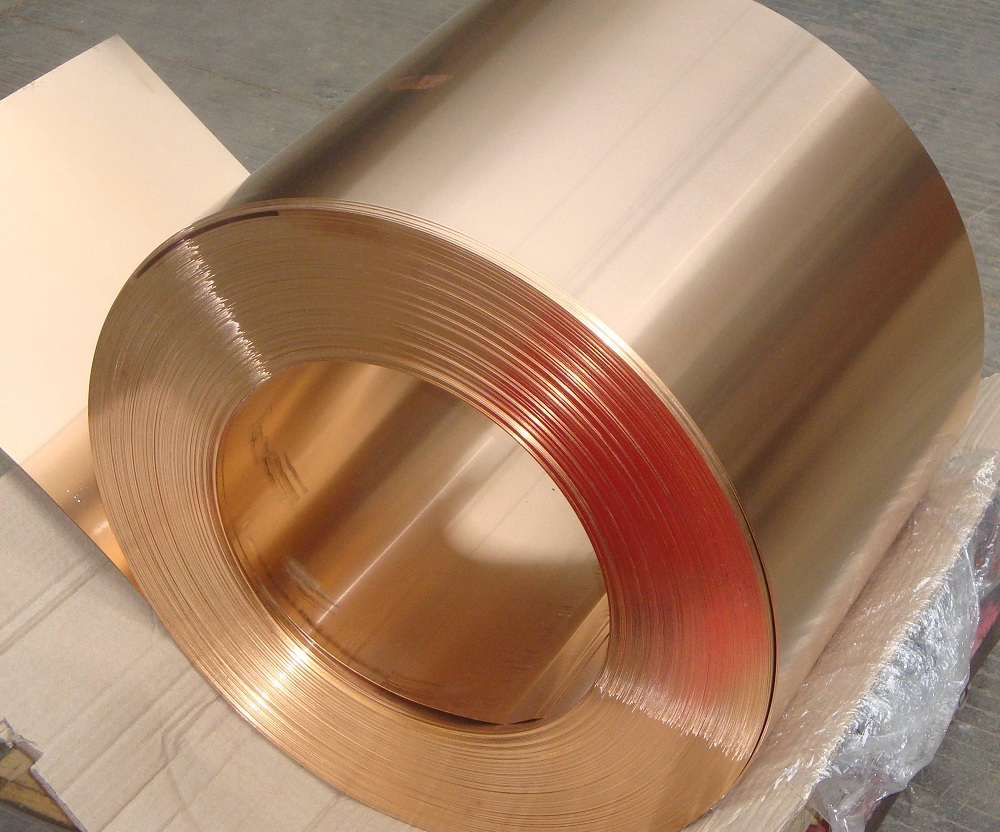

Los ntawm qhov kev taw qhia tuab, qhov tuab nominal tsawg dua 12μm yog cov ntawv ci tooj liab electrolytic nyias. Txhawm rau kom tsis txhob muaj qhov yuam kev ntawm kev ntsuas tuab, thiab qhov hnyav ib cheeb tsam yog qhia xws li cov ntawv ci tooj liab electrolytic 18 thiab 35μm thoob ntiaj teb, nws qhov hnyav ib leeg sib raug rau 153 thiab 305g / m2. ED tooj liab ntawv ci zoo cov qauv suav nrog kev ntshiab electrolytic tooj liab ntawv ci, resistivity, lub zog, elongation, weld peev xwm, porosity, qhov chaw roughness, thiab lwm yam.

3.ED tooj liab ntawv ciRaws li cov txheej txheem tsim khoom ntawm cov ntawv ci tooj liab electrolytic, nws muaj peev xwm muab faib ua cov txheej txheem ntau lawm ntawm kev npaj cov tshuaj electrolytic, electrolysis thiab post-processing.

Kev npaj cov electrolyte:

Ua ntej, muab cov khoom siv tooj liab uas muaj qhov huv siab dua 99.8% tom qab ntxuav lub tank rau hauv cov tooj liab yaj; tom qab ntawd ua noj nrog sulfuric acid do thiab peb tau txais cov tooj liab sulfate yaj. Muab cov tooj liab sulfate rau hauv lub tank thaum qhov concentration ncav cuag qhov yuav tsum tau ua. Nws yuav los ua ib qho kev sib xyaw ua ke ntawm cov kua los ntawm cov kav dej thiab lub twj tso kua mis thiab lub cell Unicom. Tom qab kev sib xyaw ua ke ntawm cov kua ruaj khov, nws tuaj yeem ua rau lub cell electrolysis muaj zog. Electrolyte xav tau ntxiv cov surfactant kom tsim nyog los xyuas kom meej tias cov nqi tooj liab particulate, Crystal orientation, roughness, porosity, thiab lwm yam cim.

Cov txheej txheem ntawm cov electrodes thiab electrolysis

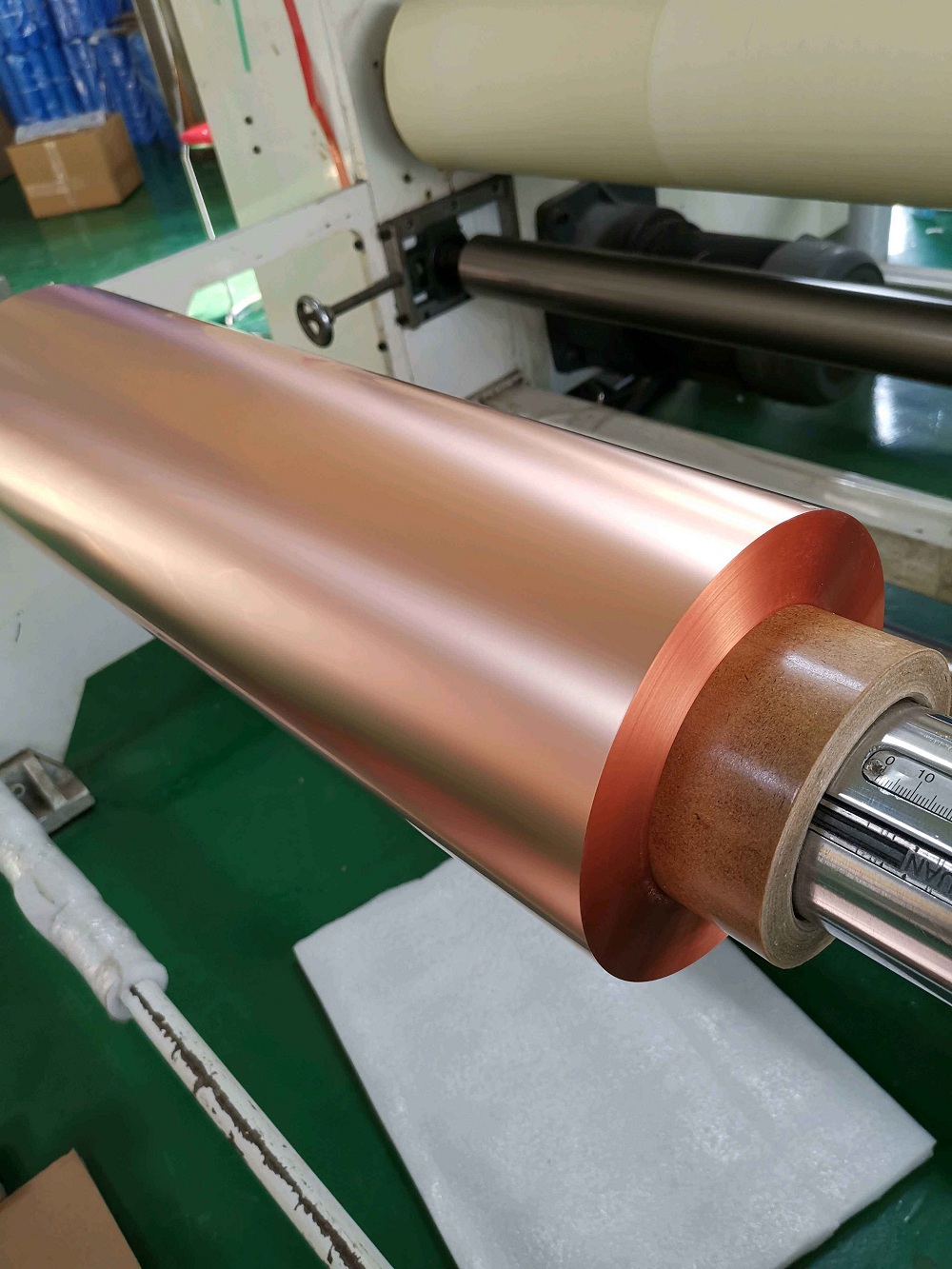

Electrolysis cathode yog lub nruas tig tau, hu ua cathode yob. Thiab nws kuj tseem siv tau cov hlau tsis muaj taub hau txawb tau ua cathode. Nws pib tso rau ntawm tooj liab cathode tom qab fais fab. Yog li ntawd, qhov dav ntawm lub log thiab txoj siv txiav txim siab qhov dav ntawm cov ntawv ci tooj liab electrolytic; thiab kev tig lossis txav mus los txiav txim siab qhov tuab ntawm cov ntawv ci tooj liab electrolytic. Tooj liab tso rau ntawm cathode raug tev tawm tas li, ntxuav, ziab, txiav, coiling thiab sim tom qab kev kho mob xa mus rau cov neeg thov kev vam meej. Ib qho electrolysis anode yog insoluble ntawm txhuas lossis txhuas alloy.

Tus txheej txheem parameter tsis yog tsuas yog cuam tshuam nrog qhov ceev ntawm electrolysis lub cathode, tab sis kuj nrog cov kua electrolyte lossis qhov concentration, kub, cathode tam sim no ceev thaum lub sijhawm electrolysis.

Tus txheej txheem parameter tsis yog tsuas yog cuam tshuam nrog qhov ceev ntawm electrolysis lub cathode, tab sis kuj nrog cov kua electrolyte lossis qhov concentration, kub, cathode tam sim no ceev thaum lub sijhawm electrolysis.

Lub titanium cathode roller spinning:

Vim tias titanium muaj kev ruaj khov tshuaj lom neeg siab thiab muaj zog heev. Nws yooj yim tev tawm ntawm qhov chaw dov thiab porosity tsawg rau cov ntawv ci tooj liab electrolytic. Titanium cathode hauv cov txheej txheem electrolytic yuav tsim cov xwm txheej passive, yog li ntawd xav tau kev ntxuav tsis tu ncua, sib tsoo, polishing, nickel, chrome. Cov tshuaj tiv thaiv corrosion kuj tseem yuav ntxiv, xws li nitro lossis nitrous aromatic lossis aliphatic compounds rau electrolyte, qhov nrawm passivation qeeb titanium cathode. Tsis tas li ntawd, qee lub tuam txhab siv stainless hlau cathode los txo tus nqi.

Lub sijhawm tshaj tawm: Lub Ib Hlis-09-2022