Cov laug cam luam tawm uas yooj ywm yog ib hom laug cam uas khoov tau uas tsim los rau ntau yam. Nws cov txiaj ntsig zoo dua li cov laug cam ib txwm muaj xws li txo qhov yuam kev sib dhos, ua tau zoo dua hauv qhov chaw nyuaj, thiab muaj peev xwm tswj tau cov kev teeb tsa hluav taws xob nyuaj dua. Cov laug cam no yog ua los ntawm cov ntawv ci tooj liab electrolytic, ib yam khoom uas tau ua pov thawj sai sai tias yog ib qho tseem ceeb tshaj plaws hauv kev lag luam hluav taws xob thiab kev sib txuas lus.

Yuav Ua Li Cas Flex Circuits

Cov voj voog flex siv rau hauv cov khoom siv hluav taws xob vim ntau yam. Raws li tau hais ua ntej lawm, nws txo qhov yuam kev sib dhos, muaj zog dua rau ib puag ncig, thiab tuaj yeem ua haujlwm nrog cov khoom siv hluav taws xob nyuaj. Txawm li cas los xij, nws kuj tseem tuaj yeem txo cov nqi zog ua haujlwm, txo qhov hnyav thiab qhov chaw xav tau, thiab txo cov ntsiab lus sib txuas uas ua rau muaj kev ruaj khov. Vim tag nrho cov laj thawj no, cov voj voog flex yog ib qho ntawm cov khoom siv hluav taws xob uas xav tau tshaj plaws hauv kev lag luam.

A Cov ntawv luam tawm yooj ywmmuaj peb yam tseem ceeb: Cov Khoom Siv Hluav Taws Xob, Cov Khoom Nplaum, thiab Cov Khoom Siv Hluav Taws Xob. Nyob ntawm seb cov qauv ntawm cov voj voog flex, peb cov khoom siv no tau npaj rau cov hluav taws xob kom ntws mus rau hauv txoj kev uas tus neeg siv khoom xav tau, thiab rau nws cuam tshuam nrog lwm cov khoom siv hluav taws xob. Cov khoom siv feem ntau rau cov nplaum ntawm lub voj voog flex yog epoxy, acrylic, PSAs, lossis qee zaum tsis muaj, thaum cov khoom siv hluav taws xob feem ntau suav nrog polyester thiab polyamide. Tam sim no, peb xav paub ntau tshaj plaws txog cov khoom siv hluav taws xob siv hauv cov voj voog no.

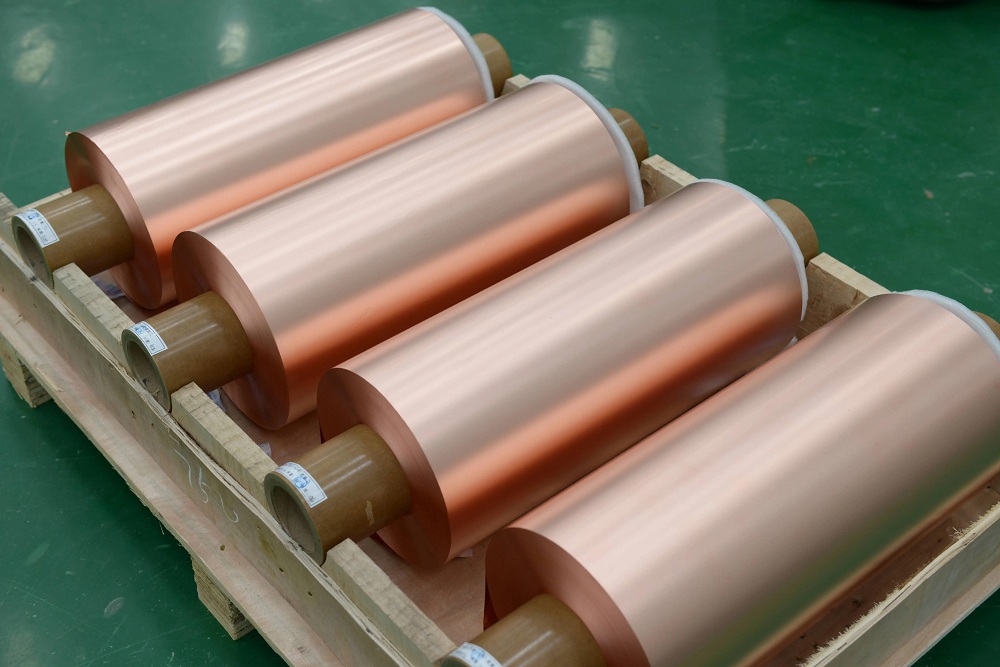

Txawm hais tias lwm yam khoom siv xws li nyiaj, carbon, thiab txhuas siv tau, cov khoom siv feem ntau siv rau cov neeg xa hluav taws xob yog tooj liab. Cov ntawv ci tooj liab yog suav tias yog cov khoom siv tseem ceeb rau kev tsim cov voj voog flex, thiab nws yog tsim los ntawm ob txoj kev: dov annealing lossis electrolysis.

Yuav Ua Li Cas Cov Ntawv Tooj Liab

Cov ntawv ci tooj liab dov annealedyog tsim los ntawm kev dov cov ntawv tooj liab uas tau cua sov, ua rau lawv nyias thiab tsim kom muaj qhov chaw tooj liab du. Cov ntawv tooj liab raug rau qhov kub thiab txias siab thiab kev nyuaj siab los ntawm txoj kev no, ua rau muaj qhov chaw du thiab txhim kho kev ua haujlwm, kev khoov tau, thiab kev coj hluav taws xob.

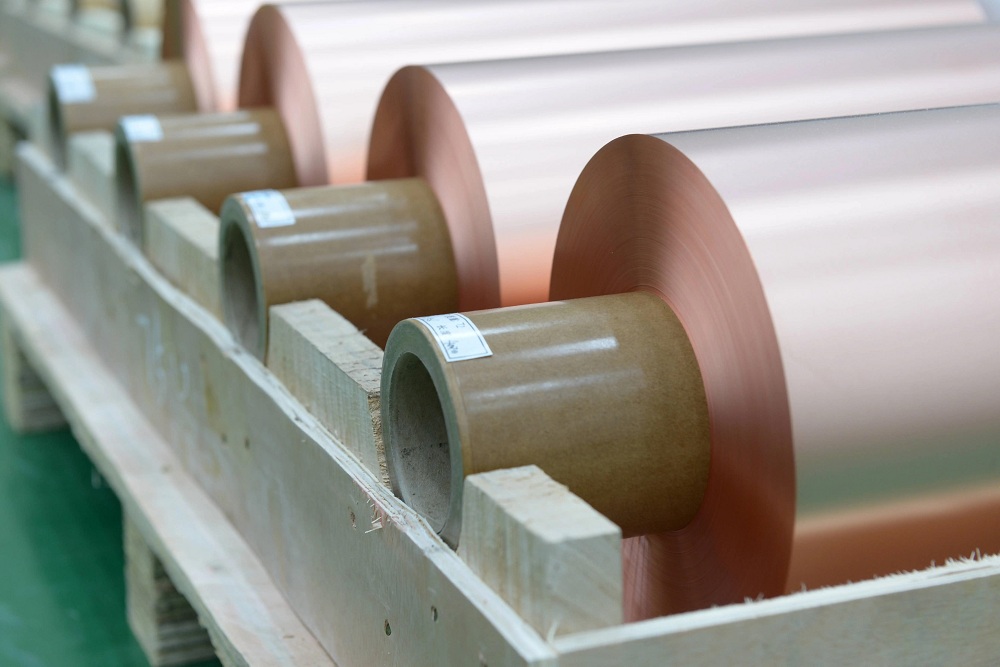

Lub caij no,electrolytic tooj liab foil yog tsim los ntawm kev siv cov txheej txheem electrolysis. Ib qho kua tooj liab yog tsim nrog sulfuric acid (nrog rau lwm cov khoom ntxiv nyob ntawm tus neeg tsim khoom cov lus qhia). Lub cell electrolytic ces khiav los ntawm cov kua, uas tom qab ntawd ua rau cov ions tooj liab los nag thiab tsaws rau ntawm qhov chaw cathode. Cov khoom ntxiv kuj tseem tuaj yeem ntxiv rau cov kua uas tuaj yeem hloov nws cov khoom sab hauv nrog rau nws cov tsos.

Cov txheej txheem electroplating no txuas ntxiv mus txog thaum lub nruas cathode raug tshem tawm ntawm cov kua. Lub nruas kuj tswj tau seb cov ntawv ci tooj liab yuav tuab npaum li cas, vim tias lub nruas uas tig sai dua kuj nyiam cov nag ntau dua, ua rau cov ntawv ci tuab.

Txawm yog siv txoj kev twg los xij, txhua daim ntawv ci tooj liab uas tsim los ntawm ob txoj kev no tseem yuav raug kho nrog kev kho kom ruaj khov, kev kho kom tiv taus cua sov, thiab kev kho kom ruaj khov (tiv thaiv kev oxidation) tom qab. Cov kev kho no ua rau cov ntawv ci tooj liab tuaj yeem khi tau zoo dua rau cov nplaum, ua kom muaj zog dua rau cua sov uas koom nrog kev tsim cov voj voog luam tawm uas yoog tau tiag tiag, thiab tiv thaiv kev oxidation ntawm cov ntawv ci tooj liab.

Rolled Annealed vs Electrolytic

Vim tias cov txheej txheem rau kev tsim cov ntawv ci tooj liab ntawm cov ntawv ci tooj liab dov thiab cov ntawv ci tooj liab electrolytic sib txawv, lawv kuj muaj cov txiaj ntsig thiab qhov tsis zoo sib txawv.

Qhov sib txawv tseem ceeb ntawm ob daim ntawv ci tooj liab yog nyob rau hauv lawv cov qauv. Daim ntawv ci tooj liab dov annealed yuav muaj cov qauv kab rov tav ntawm qhov kub ib txwm, uas tom qab ntawd hloov mus rau hauv cov qauv siv lead ua lamellar thaum raug siab thiab kub. Lub caij no, cov ntawv ci tooj liab electrolytic khaws nws cov qauv columnar ntawm ob qho tib si kub ib txwm thiab siab thiab kub.

Qhov no ua rau muaj qhov sib txawv ntawm kev coj ua hluav taws xob, kev ywj pheej, kev khoov tau, thiab tus nqi ntawm ob hom ntawv ci tooj liab. Vim tias cov ntawv ci tooj liab uas dov tau feem ntau du dua, lawv muaj kev coj ua hluav taws xob ntau dua thiab tsim nyog dua rau cov xov hlau me me. Lawv kuj muaj kev ywj pheej ntau dua thiab feem ntau khoov tau ntau dua li cov ntawv ci tooj liab electrolytic.

Txawm li cas los xij, qhov yooj yim ntawm txoj kev electrolysis ua kom ntseeg tau tias cov ntawv ci tooj liab electrolytic muaj tus nqi qis dua li cov ntawv ci tooj liab dov. Nco ntsoov tias lawv yuav yog qhov kev xaiv tsis zoo rau cov kab me me, thiab lawv muaj qhov tsis kam khoov qis dua li cov ntawv ci tooj liab dov.

Xaus lus, cov ntawv ci tooj liab electrolytic yog qhov kev xaiv pheej yig zoo li cov neeg coj hluav taws xob hauv lub voj voog luam tawm yooj ywm. Vim yog qhov tseem ceeb ntawm lub voj voog flex hauv cov khoom siv hluav taws xob thiab lwm yam lag luam, nws, ua rau cov ntawv ci tooj liab electrolytic yog cov khoom siv tseem ceeb thiab.

Lub sijhawm tshaj tawm: Cuaj hlis-14-2022