Nrog rau kev thov siab hauv ntau yam khoom lag luam, tooj liab yog pom tias yog cov khoom siv ntau yam.

Cov ntawv ci tooj liab yog tsim los ntawm cov txheej txheem tsim khoom tshwj xeeb hauv lub tshuab ci ntawv ci uas suav nrog ob qho tib si kub thiab txias dov.

Nrog rau txhuas, tooj liab tau siv dav hauv cov khoom lag luam ua cov khoom siv tau ntau yam ntawm cov hlau uas tsis yog hlau. Tshwj xeeb tshaj yog nyob rau xyoo tas los no, qhov kev thov rau cov ntawv ci tooj liab tau nce siab rau cov khoom siv hluav taws xob suav nrog xov tooj ntawm tes, lub koob yees duab digital, thiab cov khoom siv IT.

Kev tsim cov ntawv ci

Cov ntawv ci tooj liab nyias nyias yog tsim los ntawm electrodeposition lossis dov. Rau electrodeposition tooj liab qib siab yuav tsum tau yaj rau hauv cov kua qaub kom tsim tau cov electrolyte tooj liab. Cov kua electrolyte no raug pumped rau hauv cov nruas uas tig ib nrab uas tau them hluav taws xob. Ntawm cov nruas no ib zaj duab xis tooj liab nyias nyias yog electrodeposited. Cov txheej txheem no kuj hu ua plating.

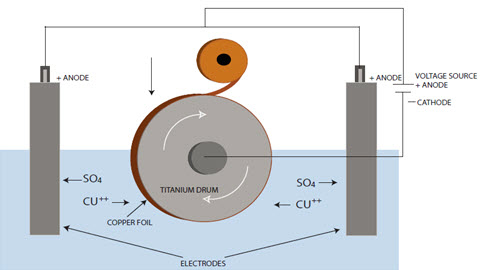

Hauv cov txheej txheem tsim tooj liab electrodeposited, cov ntawv ci tooj liab raug tso rau ntawm lub nruas titanium rotating los ntawm cov kua tooj liab qhov twg nws txuas nrog DC voltage qhov chaw. Lub cathode raug txuas rau lub nruas thiab lub anode raug submerged hauv cov kua tooj liab electrolyte. Thaum lub teb hluav taws xob raug siv, tooj liab raug tso rau ntawm lub nruas thaum nws tig qeeb heev. Qhov chaw tooj liab ntawm sab nruas yog du thaum sab nraud yog ntxhib. Qhov qeeb qeeb ntawm lub nruas ceev, qhov tuab dua tooj liab tau txais thiab vice versa. Tooj liab raug rub thiab sau rau ntawm qhov chaw cathode ntawm lub nruas titanium. Sab matte thiab nruas ntawm cov ntawv ci tooj liab mus dhau ntau lub voj voog kho kom tooj liab tuaj yeem tsim nyog rau PCB fabrication. Cov kev kho mob txhim kho kev sib txuas ntawm tooj liab thiab dielectric interlayer thaum lub sijhawm tooj liab clad lamination txheej txheem. Lwm qhov zoo ntawm kev kho mob yog ua raws li cov neeg sawv cev tiv thaiv tarnish los ntawm kev qeeb qeeb oxidation ntawm tooj liab.

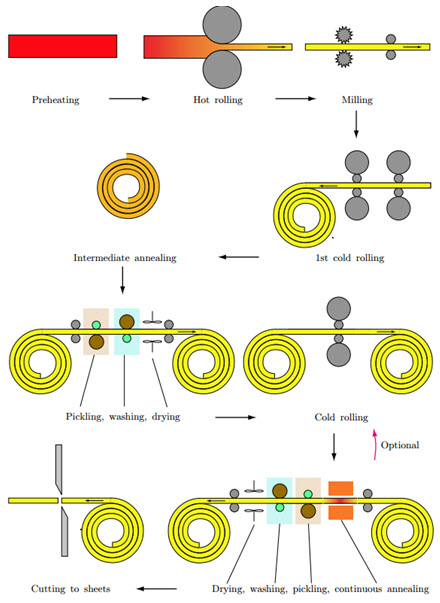

Daim Duab 1:Cov Txheej Txheem Tsim Tooj Liab Electrodeposited Daim Duab 2 qhia txog cov txheej txheem tsim cov khoom tooj liab dov. Cov khoom siv dov yog muab faib ua peb hom; uas yog, cov tshuab dov kub, cov tshuab dov txias, thiab cov tshuab ci ntawv ci.

Cov kauj ntawm cov ntawv ci nyias nyias raug tsim thiab dhau los ntawm kev kho tshuaj lom neeg thiab kho tshuab kom txog thaum lawv raug tsim rau hauv lawv cov duab kawg. Ib daim duab qhia txog cov txheej txheem dov ntawm cov ntawv ci tooj liab tau muab rau hauv Daim Duab 2. Ib lub thaiv ntawm cov tooj liab cam khwb cia (kwv yees li qhov ntev: 5mx1mx130mm) raug cua sov txog li 750 ° C. Tom qab ntawd, nws raug kub dov rov qab hauv ntau kauj ruam mus rau 1/10 ntawm nws cov tuab qub. Ua ntej thawj zaug dov txias, cov nplai uas pib los ntawm kev kho cua sov raug coj mus los ntawm kev sib tsoo. Hauv cov txheej txheem dov txias, qhov tuab raug txo kom txog li 4 hli thiab cov ntawv raug tsim rau cov kauj. Cov txheej txheem raug tswj hwm hauv txoj hauv kev uas cov khoom siv tsuas yog ntev dua thiab tsis hloov nws qhov dav. Raws li cov ntawv tsis tuaj yeem tsim ntxiv hauv lub xeev no (cov khoom siv tau ua haujlwm tawv heev) lawv raug kho cua sov thiab raug cua sov txog li 550 ° C.

Lub sijhawm tshaj tawm: Lub Yim Hli-13-2021