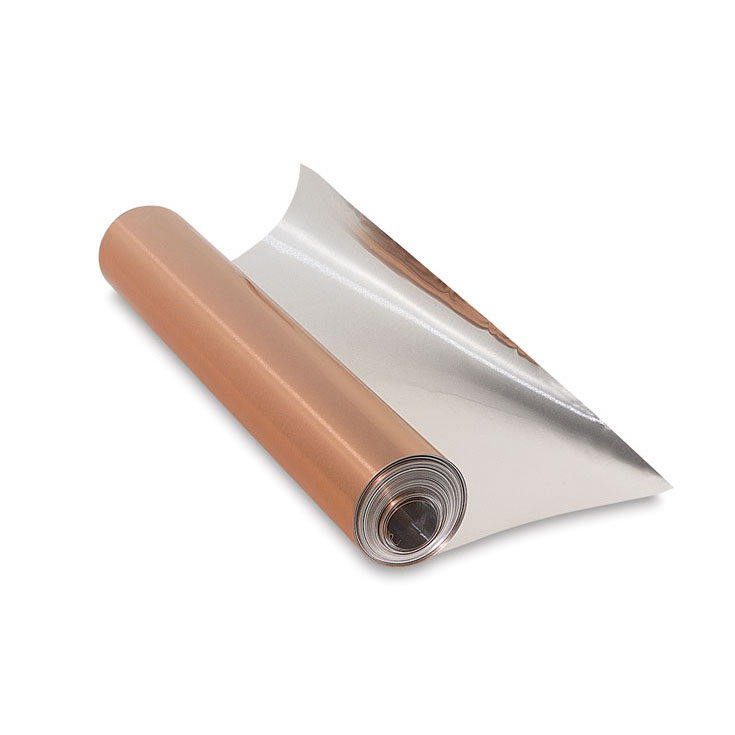

Daim Ntawv Pov Thawj IOS Tuam Tshoj Hte Ra Rolled Annealed Copper Foil rau PCB Ccl

Peb vam khom lub zog thev naus laus zis ruaj khov thiab txuas ntxiv tsim cov thev naus laus zis zoo kom tau raws li qhov xav tau ntawm IOS Daim Ntawv Pov Thawj Tuam Tshoj Hte Ra Rolled Annealed Copper Foil rau PCB Ccl, Peb cov khoom lag luam tau lees paub dav thiab ntseeg tau los ntawm cov neeg siv thiab tuaj yeem ua tiav cov kev xav tau kev lag luam thiab kev sib raug zoo hloov pauv tas li.

Peb vam khom lub zog khov kho thiab tsim cov thev naus laus zis zoo heev kom tau raws li qhov xav tau ntawmTuam Tshoj Cov Ntawv Nyiaj Tooj Liab, Cov Ntawv Nyiaj Tooj Liab DovPeb xav koom tes nrog cov tuam txhab txawv teb chaws uas mob siab rau qhov zoo tiag tiag, kev muab khoom ruaj khov, muaj peev xwm zoo thiab kev pabcuam zoo. Peb tuaj yeem muab tus nqi sib tw tshaj plaws nrog qhov zoo, vim peb tau ua tus kws tshwj xeeb ntau dua. Koj tuaj yeem tuaj xyuas peb lub tuam txhab txhua lub sijhawm.

Kev Taw Qhia Txog Khoom

Cov khoom tooj liab uas raug tso tawm hauv huab cua feem ntau yuav raug oxidation thiab tsim cov tooj liab carbonate yooj yim, uas muaj kev tiv thaiv siab, kev ua hluav taws xob tsis zoo thiab kev poob hluav taws xob siab; tom qab tin plating, cov khoom tooj liab tsim cov yeeb yaj kiab tin dioxide hauv huab cua vim yog cov khoom ntawm tin hlau nws tus kheej kom tiv thaiv kev oxidation ntxiv. Tin kuj tseem tuaj yeem tsim cov yeeb yaj kiab zoo sib xws hauv halogen, yog li cov khoom tooj liab tom qab plating muaj kev tiv thaiv corrosion zoo thiab weldability, thiab tib lub sijhawm muaj qee lub zog thiab hardness, yog li lawv siv dav hauv cov khoom siv hluav taws xob thiab hluav taws xob; vim tias tin hlau tsis muaj tshuaj lom thiab tsis muaj saj, cov khoom tom qab plating kuj siv dav hauv kev lag luam zaub mov. Cov ntawv ci tooj liab tinned tsim los ntawm CIVEN METAL muaj qhov tiav zoo thiab cov txheej tin tuab. Lawv tuaj yeem annealed thiab slit raws li cov neeg siv khoom xav tau.

Cov Khoom Siv Tseem Ceeb

● Kev ua kom raug siabCov Ntawv Nyiaj Tooj Liab Dov, Cu (JIS: C1100/ASTM: C11000) cov ntsiab lus ntau dua 99.96%

Cov Khoom Siv Hauv Paus Thickness Ntau Yam

● 0.035mm ~ 0.15mm (0.0013 ~ 0.0059 nti)

Qhov Dav Dav ntawm Cov Khoom Siv

● ≤300mm (≤11.8 nti)

Cov Khoom Siv Hauv Paus

● Raws li cov neeg siv khoom xav tau

Daim Ntawv Thov

● Cov khoom siv hluav taws xob thiab kev lag luam electronics, civil (xws li: dej haus ntim thiab cov khoom siv sib cuag zaub mov);

Cov Kev Ntsuas Kev Ua Tau Zoo

| Cov khoom | Cov Tin Plating Uas Siv Tau | Tin Plating uas tsis yog vuam |

| Qhov Dav Dav | ≤600mm (≤23.62inches) | |

| Qhov ntau thiab tsawg | 0.012~0.15 hli (0.00047 nti~0.0059 nti) | |

| Tin txheej Thickness | ≥0.3µm | ≥0.2µm |

| Cov ntsiab lus ntawm Tin Txheej | 65 ~ 92% (Tuaj yeem kho cov ntsiab lus tin raws li cov txheej txheem vuam ntawm cov neeg siv khoom) | 100% Ntshiab Tin |

| Kev Tiv Thaiv Nto Ntawm Tin Txheej(Ω) | 0.3~0.5 | 0.1~0.15 |

| Kev nplaum | 5B | |

| Lub zog tensile | Kev Ua Haujlwm ntawm Cov Khoom Siv Hauv Paus Tom Qab Plating ≤10% | |

| Kev ntev | Kev Ua Haujlwm ntawm Cov Khoom Siv Hauv Paus Tom Qab Plating ≤6% | |

Peb vam khom lub zog thev naus laus zis ruaj khov thiab txuas ntxiv tsim cov thev naus laus zis zoo kom tau raws li qhov xav tau ntawm IOS Daim Ntawv Pov Thawj Tuam Tshoj Hte Ra Rolled Annealed Copper Foil rau PCB Ccl, Peb cov khoom lag luam tau lees paub dav thiab ntseeg tau los ntawm cov neeg siv thiab tuaj yeem ua tiav cov kev xav tau kev lag luam thiab kev sib raug zoo hloov pauv tas li.

Daim Ntawv Pov Thawj IOSTuam Tshoj Cov Ntawv Nyiaj Tooj Liab, Cov Ntawv Nyiaj Tooj Liab Dov, Peb xav koom tes nrog cov tuam txhab txawv teb chaws uas mob siab rau qhov zoo tiag tiag, kev muab khoom ruaj khov, muaj peev xwm zoo thiab kev pabcuam zoo. Peb tuaj yeem muab tus nqi sib tw tshaj plaws nrog qhov zoo, vim peb tau tshwj xeeb ntau dua. Koj tuaj yeem tuaj xyuas peb lub tuam txhab txhua lub sijhawm.