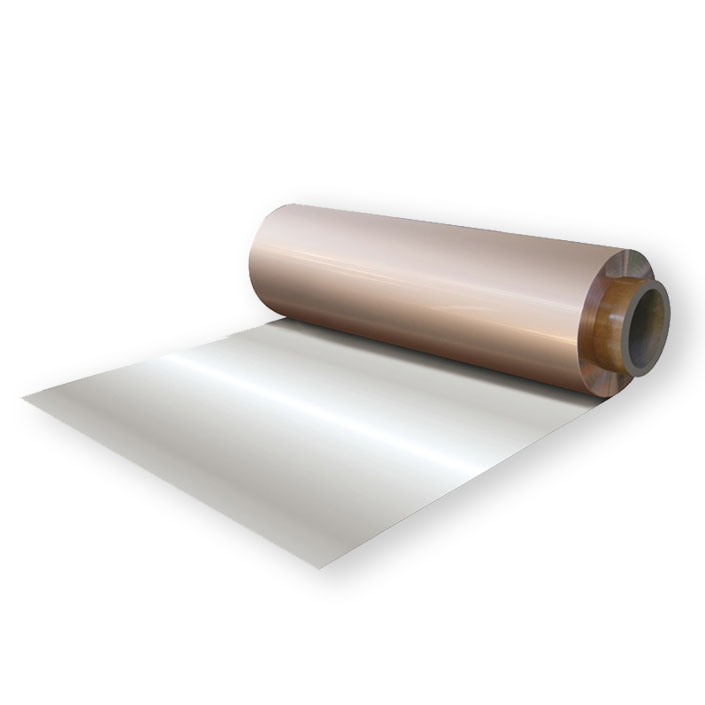

Hoobkas Muag Tuam Tshoj Electrolytic Tooj Ntawv Nyiaj Rau Roj Teeb Anode Substrate

Peb txoj kev vam meej nyob ntawm cov khoom siv tsim kho zoo heev, cov txuj ci zoo heev thiab cov thev naus laus zis txuas ntxiv muaj zog rau Lub Hoobkas Muag Tuam Tshoj Electrolytic Copper Foil rau Roj Teeb Anode Substrate, Cov neeg siv khoom cov txiaj ntsig thiab kev txaus siab yog peb lub hom phiaj loj tshaj plaws. Koj yuav tsum tiv tauj peb. Muab lub sijhawm rau peb, muab rau koj qhov xav tsis thoob.

Peb txoj kev vam meej nyob ntawm cov cuab yeej siv uas tau tsim kho zoo heev, cov txuj ci zoo heev thiab cov cuab yeej siv thev naus laus zis uas muaj zog tas mus li rauGn-Bccf, Peb zoo siab los muab peb cov khoom rau txhua tus kiv cua tsheb thoob plaws ntiaj teb nrog peb cov kev pabcuam yooj ywm, ceev ceev thiab cov qauv tswj xyuas zoo tshaj plaws uas tau pom zoo thiab qhuas los ntawm cov neeg siv khoom.

Kev Taw Qhia Txog Khoom

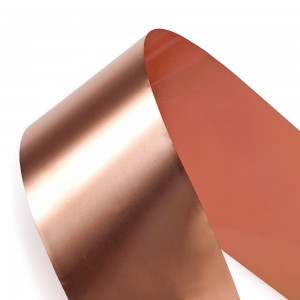

Hlau nickel muaj kev ruaj khov siab hauv huab cua, muaj peev xwm passivation muaj zog, tuaj yeem tsim cov zaj duab xis passivation nyias heev hauv huab cua, tuaj yeem tiv taus qhov corrosion ntawm alkali thiab acids, yog li cov khoom ruaj khov hauv kev ua haujlwm thiab alkaline ib puag ncig, tsis yooj yim rau discolor, tsuas yog tuaj yeem oxidized saum toj no 600 ℃; nickel plating txheej muaj zog adhesion, tsis yooj yim poob tawm; nickel plating txheej tuaj yeem ua rau qhov chaw ntawm cov khoom nyuaj dua, tuaj yeem txhim kho cov khoom hnav tsis kam thiab acid thiab alkali corrosion tsis kam, cov khoom hnav tsis kam, corrosion, kev tiv thaiv xeb kev ua tau zoo heev. Vim yog qhov nyuaj ntawm qhov chaw ntawm cov khoom nickel plated, nickel plated crystals yog qhov zoo heev, nrog rau kev polishing siab, polishing tuaj yeem ncav cuag daim iav tsos, hauv huab cua tuaj yeem tswj tau hauv lub sijhawm ntev huv, yog li nws kuj tseem siv rau kev kho kom zoo nkauj. Cov ntawv ci tooj liab nickel plated tsim los ntawm CIVEN METAL muaj qhov chaw tiav zoo heev thiab lub tiaj tus. Lawv kuj tseem degreased thiab tuaj yeem yooj yim laminated nrog lwm cov ntaub ntawv. Tib lub sijhawm, peb kuj tuaj yeem kho peb cov ntawv ci tooj liab nickel-plated los ntawm annealing thiab slitting raws li cov neeg siv khoom xav tau.

Cov Khoom Siv Tseem Ceeb

● Cov Ntawv Nyiaj Tooj Liab Uas Muaj Kev Ntsuas Siab (JIS:C1100/ASTM:C11000) Cov ntsiab lus Cu ntau dua 99.96%

Cov Khoom Siv Hauv Paus Thickness Ntau Yam

● 0.012 hli ~ 0.15 hli (0.00047 nti ~ 0.0059 nti)

Qhov Dav Dav ntawm Cov Khoom Siv

● ≤600mm (≤23.62inches)

Cov Khoom Siv Hauv Paus

● Raws li cov neeg siv khoom xav tau

Daim Ntawv Thov

● Cov khoom siv hluav taws xob, khoom siv hluav taws xob, roj teeb, kev sib txuas lus, kho vajtse thiab lwm yam lag luam;

Cov Kev Ntsuas Kev Ua Tau Zoo

| Cov khoom | Siv tauNickelKev plating | Tsis yog-weldNickelKev plating |

| Qhov Dav Dav | ≤600mm (≤23.62inches) | |

| Qhov ntau thiab tsawg | 0.012~0.15 hli (0.00047 nti~0.0059 nti) | |

| Nickel Txheej Thickness | ≥0.4µm | ≥0.2µm |

| Cov ntsiab lus ntawm Nickel Txheej | 80 ~ 90% (Tuaj yeem kho cov ntsiab lus nickel raws li cov txheej txheem vuam ntawm cov neeg siv khoom) | 100% Nickel Ntshiab |

| Kev Tiv Thaiv Nto Ntawm Nickel Txheej(Ω) | ≤0.1 | 0.05~0.07 |

| Kev nplaum | 5B | |

| Lub zog tensile | Kev Ua Haujlwm ntawm Cov Khoom Siv Hauv Paus Tom Qab Plating ≤10% | |

| Kev ntev | Kev Ua Haujlwm ntawm Cov Khoom Siv Hauv Paus Tom Qab Plating ≤6% | |

Peb txoj kev vam meej nyob ntawm cov khoom siv tsim kho zoo heev, cov txuj ci zoo heev thiab cov thev naus laus zis txuas ntxiv muaj zog rau Lub Hoobkas Muag Tuam Tshoj Electrolytic Copper Foil rau Roj Teeb Anode Substrate, Cov neeg siv khoom cov txiaj ntsig thiab kev txaus siab yog peb lub hom phiaj loj tshaj plaws. Koj yuav tsum tiv tauj peb. Muab lub sijhawm rau peb, muab rau koj qhov xav tsis thoob.

Hoobkas Muag KhoomGn-Bccf, Peb zoo siab los muab peb cov khoom rau txhua tus kiv cua tsheb thoob plaws ntiaj teb nrog peb cov kev pabcuam yooj ywm, ceev ceev thiab cov qauv tswj xyuas zoo tshaj plaws uas tau pom zoo thiab qhuas los ntawm cov neeg siv khoom.