Beryllium Tooj Liab Ntawv Nyiaj

Kev Taw Qhia Txog Khoom

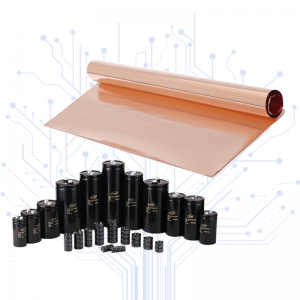

Beryllium Tooj Liab Ntawv Nyiaj yog ib hom hlau tooj liab uas muaj cov khoom siv kho tshuab, lub cev, tshuaj lom neeg thiab kev tiv taus corrosion zoo heev. Nws muaj qhov txwv siab, qhov txwv elastic, lub zog tawm los thiab qhov txwv qaug zog raws li hlau tshwj xeeb tom qab kev kho tshuaj thiab kev laus. Nws kuj muaj kev coj ua siab, kev coj ua thermal, qhov nyuaj thiab hnav tsis kam, kev nkag siab siab thiab kev tiv taus corrosion uas nws tau siv dav los hloov hlau hauv kev tsim ntau hom pwm ntxig, tsim cov pwm precision thiab cov pwm nyuaj, vuam electrode khoom casting tshuab, txhaj tshuaj molding tshuab 'punches thiab lwm yam.

Beryllium Copper Foil daim ntawv thov yog micro-motor txhuam, xov tooj ntawm tes roj teeb, khoos phis tawj connectors, txhua yam ntawm kev sib txuas lus, springs, clips, gaskets, diaphragms, zaj duab xis thiab lwm yam.

Nws yog ib qho tseem ceeb uas tsis tuaj yeem ua rau muaj kev lag luam tseem ceeb rau lub teb chaws kev lag luam

Cov Ntsiab Lus

| Cov hlau tsis muaj. | Cov Tshuaj Lom Zem Tseem Ceeb | |||

| ASTM | Cu | Ni | Co | Be |

| C17200 | Remin | ① | ① | 1.80-2.10 |

“①”: Ni+Co ≥0.20%; Ni+Fe+Co≤0.60%;

Cov Khoom

| Qhov Ceev | 8.6g/cm3 |

| Qhov nyuaj | 36-42HRC |

| Kev coj ua hluav taws xob | ≥18% IACS |

| Lub zog tensile | ≥1100Mpa |

| Kev Ua Kub | ≥105w/m.k20℃ |

Cov Lus Qhia Tshwj Xeeb

| Hom | Cov kauj thiab cov ntawv |

| Qhov tuab | 0.02 ~ 0.1 hli |

| Dav | 1.0 ~ 625 hli |

| Kev kam rau siab hauv tuab thiab dav | Raws li tus qauv YS/T 323-2002 lossis ASTMB 194-96. |